GSM Industrial partnered with a leading Berks County manufacturer to deliver a complete dust collection system upgrade that improved workplace air quality while addressing critical structural and operational challenges. This turnkey project showcases our ability to manage complex industrial projects from concept to completion—delivering exceptional results on time and within budget, even with the most challenging constraints.

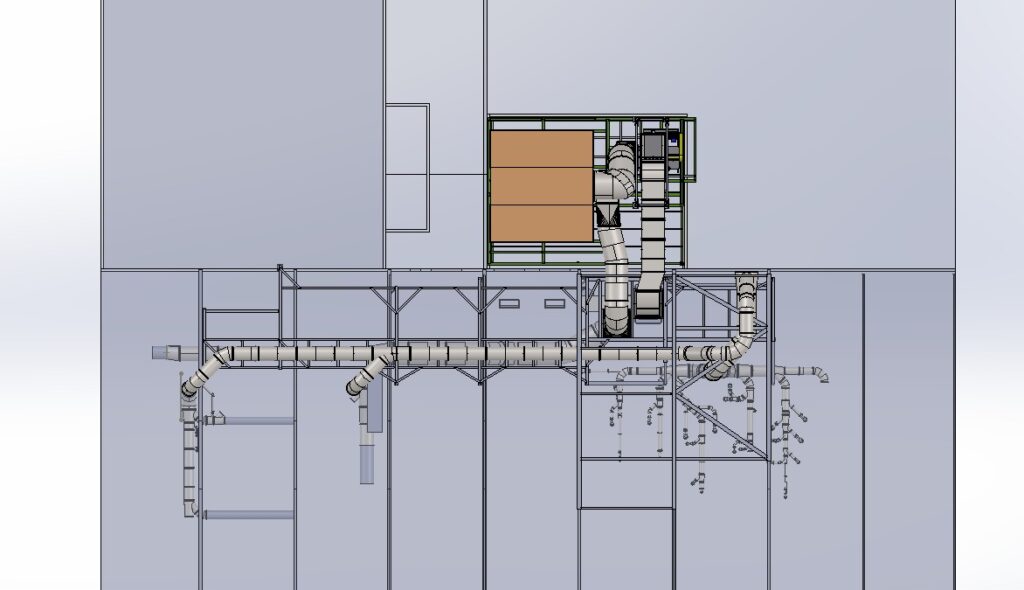

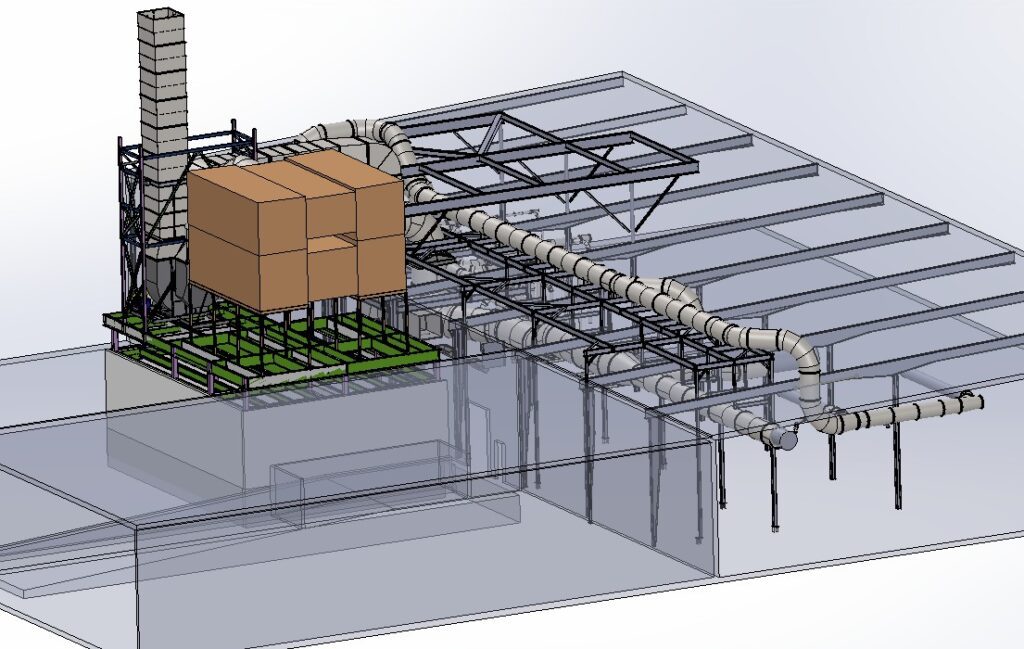

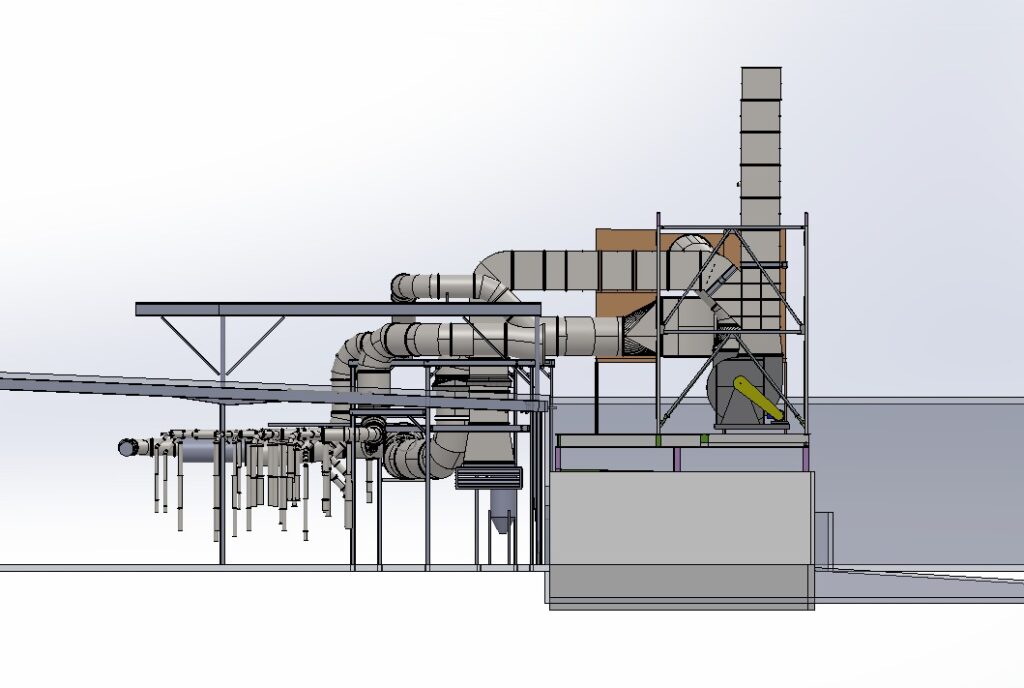

The comprehensive scope included replacing an undersized dust collector with a higher-capacity unit, completely redesigning and fabricating custom ductwork throughout the facility, installing a new exhaust stack, and engineering robust structural support systems. The project’s successful completion demonstrates GSM Industrial’s unique ability to handle the dirty, dangerous, and difficult industrial projects that require both technical expertise and meticulous execution.

Working collaboratively with the customer’s engineering team, we designed and installed new structural steel supports across five building bays, effectively removing utility loads from the roof while optimizing the dust collection system’s efficiency. Our solutions not only resolved immediate air quality concerns but also supported the customer’s facility expansion goals by enabling a loading dock extension project to proceed simultaneously.

The customer’s production demands allowed minimal facility downtime, restricting installation work to specific scheduled weekends and holidays. Most critically, our team needed to execute major system components during two key shutdown periods: Fourth of July week and Christmas week.

How We Delivered: Our project management team developed a detailed phase-by-phase implementation plan that maximized productivity during available windows. We deployed dual installation crews working around the clock during critical periods, ensuring on-schedule completion without disrupting the customer’s operations.

The project required precise coordination to ensure the new dust collector, fan assembly, and exhaust stack would properly integrate with a simultaneously constructed loading dock expansion being built by third-party contractors.

How We Delivered: GSM Industrial led weekly coordination meetings with all stakeholders, ensuring alignment across contractors. Our in-house design team spent extensive hours on-site capturing precise field measurements, ensuring first-time-right fabrication and efficient installation.

Limited available ground space meant creative solutions were needed to accommodate the significantly larger dust collection system without compromising operational flow.

How We Delivered: Our engineering team developed an innovative design that positioned the new dust collector above the loading dock expansion, maximizing facility square footage while minimizing duct runs for optimal system performance and energy efficiency.

Throughout this complex project, GSM Industrial maintained our unwavering commitment to safety excellence. Our comprehensive safety protocols ensured zero incidents despite the challenges of elevated work, heavy equipment installation, and 24-hour operations during peak periods.

By integrating design, fabrication, and installation capabilities, we eliminated the inefficiencies and markup cascades that occur when multiple vendors handle different project phases. Our turnkey approach delivered significant cost advantages compared to piecemeal implementation, while our durable, high-quality construction will minimize maintenance costs over the system’s operational life.

When field conditions or schedule adjustments required quick decisions, GSM Industrial’s experienced team provided immediate solutions rather than delays. Our average employee tenure of 13 years means your project benefits from seasoned professionals who understand industrial realities and can adapt seamlessly to evolving requirements.

This project exemplifies why industrial operations leaders trust GSM Industrial when facing their most challenging infrastructure upgrades. When production efficiency and timeline compliance are non-negotiable, our turnkey capability delivers advantages that fragmented contractor approaches simply cannot match.

For maintenance and operations teams running lean, GSM Industrial functions as a seamless extension of your capabilities—handling complex projects with minimal oversight requirements. Our collaborative approach means you spend less time managing contractors and more time focusing on your core operations.

Engineers and project managers appreciate our technical expertise and attention to detail, from precision CAD design through quality-controlled fabrication to expert installation. When your reputation depends on project success, GSM Industrial provides the predictable performance and documented results you need.

Beyond improving air quality, properly designed dust collection systems reduce maintenance requirements on production equipment, extend filter life through efficient airflow management, lower energy consumption compared to outdated systems, and can reduce compliance documentation burdens through better particulate capture.

Key ROI considerations include reduced maintenance costs, improved equipment longevity, decreased production interruptions, lower energy consumption, reduced housekeeping requirements, and potential insurance premium benefits. Additionally, improved air quality often contributes to higher workforce productivity and reduced absenteeism.

Our approach combines extensive prefabrication in our controlled shop environment, detailed phasing plans that maximize off-shift work, and experienced installation crews accustomed to tight timeline execution. We develop contingency plans for each critical path element and maintain flexible crew scheduling to adapt to changing production requirements.

GSM Industrial designs with maintenance accessibility as a priority, ensuring filter changes, motor service, and ductwork inspection can be performed efficiently. We can provide comprehensive maintenance documentation, recommended service schedules, and training for maintenance personnel to maximize system longevity.

Whether you’re upgrading critical infrastructure, expanding production capabilities, or resolving complex operational challenges, GSM Industrial delivers the comprehensive solutions and predictable performance that industrial leaders depend on.

Our proven approach combines engineering expertise, precision fabrication capabilities, and skilled field installation—all unified through experienced project management that keeps your priorities at the center of everything we do.

Contact us today to discuss how our turnkey industrial solutions can address your most challenging projects.

Note: Due to strict client confidentiality agreements, photographs of this installation are not available for public display. The project specifications and performance data have been shared with permission. We’d be happy to discuss similar solutions for your facility and can provide appropriate visual references during consultation meetings.