Clean Air, Safe Operations, and Smart Partnerships

In today’s industrial environments, maintaining clean air isn’t optional — it’s essential for compliance, worker safety, and reliable production. Dust, fumes, and airborne contaminants threaten both people and processes, often leading to downtime, equipment failure, or costly fines.

That’s where GSM Industrial comes in. We don’t build our own line of air pollution control equipment — we build complete, integrated solutions. By sourcing the right systems from trusted manufacturers and combining them with our in-house fabrication, installation, and field expertise, we help clients achieve safe, compliant, and efficient operations that stand the test of time.

Why Air Pollution Control Matters

Industrial processes like grinding, welding, cutting, or mixing generate airborne particulates and gases that can quickly exceed OSHA’s allowable limits. Without proper collection and ventilation, these emissions can lead to:

- Workplace safety hazards, including fire risk or respiratory exposure.

- Regulatory violations under OSHA and the EPA’s Clean Air Act.

- Reduced equipment performance from buildup and contamination.

- Costly downtime due to maintenance or shutdowns.

A properly designed air pollution control system — whether it includes dust collection, thermal oxidation, or exhaust ventilation — helps prevent these issues, ensuring cleaner air, better productivity, and long-term compliance.

Types of Industrial Air Pollution Control Systems

Because every facility and process is different, GSM Industrial partners with a range of reputable equipment providers to deliver the best-fit solution. Our team then fabricates the ductwork, supports, and exhaust systems that make it all work together.

Regenerative Thermal Oxidizers (RTOs):

RTOs reduce volatile organic compounds (VOCs) and hazardous air pollutants by oxidizing them at high temperatures. We coordinate with trusted manufacturers to source RTO units, then manage the ducting, structural supports, and installation to integrate them safely into your process.

Dust Collection Systems:

From baghouse units to cartridge collectors, dust collection systems capture fine particles at the source. GSM designs and fabricates the supporting steel, manifolds, and ductwork to ensure maximum airflow efficiency and minimal downtime during installation.

Scrubbers and Filtration Systems:

When wet scrubbers or filtration systems are required for gas or particulate removal, we provide turnkey installation and mechanical integration, ensuring your system performs to spec and remains accessible for maintenance.

Because we’re not tied to any single product line, we can objectively evaluate options and build the best system for your specific facility and application.

Meeting OSHA and Environmental Compliance Standards

Compliance isn’t just about meeting today’s regulations — it’s about future-proofing your operation. OSHA’s 29 CFR 1910.1000 defines permissible exposure limits for airborne contaminants, while the EPA’s Clean Air Act regulates emissions by industry.

GSM Industrial helps you stay compliant by focusing on:

- Proper capture and exhaust design to meet airflow requirements.

- Efficient filtration and ducting layouts that reduce emissions.

- Safe access for maintenance and filter replacement.

- Full documentation to support inspection or audit readiness.

Our integrated approach ensures your air quality systems meet standards today — and adapt easily to tomorrow’s requirements.

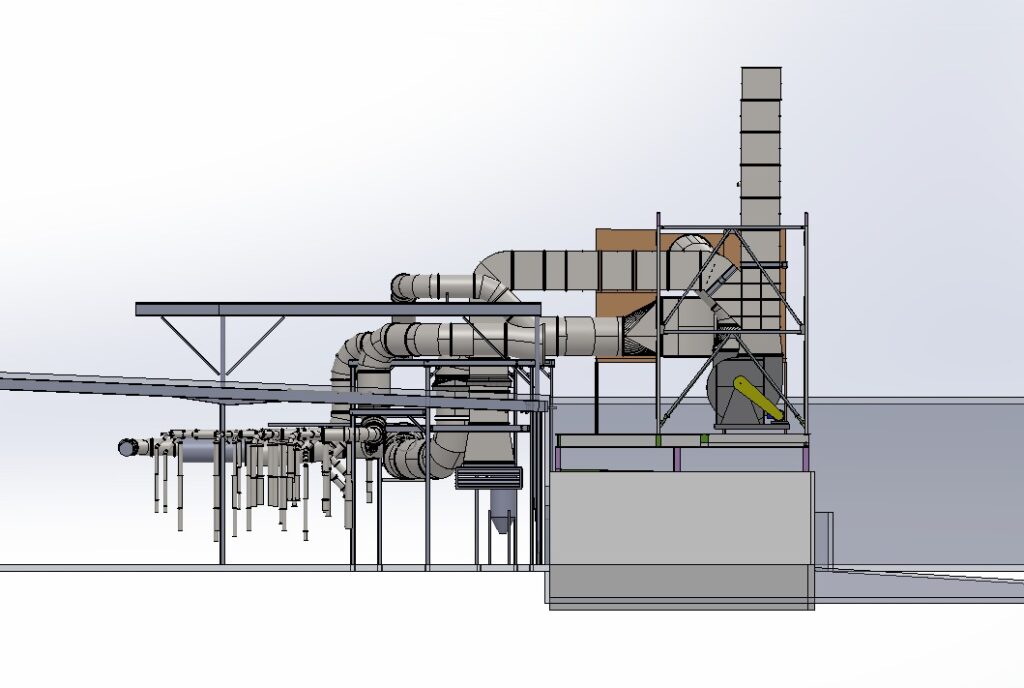

Case Study: Dust Collection System Upgrade in Berks County, PA

When a leading Berks County manufacturer needed to upgrade its outdated dust collection system, GSM Industrial provided the turnkey solution.

We sourced a high-capacity collector that met the client’s performance and space constraints, then handled everything else — from custom ductwork and steel support fabrication to on-site installation and integration.

Key project achievements:

- 1,080 feet of ductwork fabricated and installed.

- 76,000 pounds of structural steel engineered for support.

- 25-foot exhaust stack and 56-foot elevated collector platform.

- Zero operational disruptions, even during limited shutdown windows.

By working closely with the client’s engineering team and coordinating with other contractors, GSM delivered a safer, more efficient system that met compliance goals while supporting the facility’s expansion.

The Long-Term Benefits of Partnering with GSM Industrial

When you partner with GSM Industrial, you gain more than a contractor — you gain a team of problem-solvers committed to your success.

A properly integrated air pollution control system delivers:

- Improved air quality and worker safety.

- Lower energy costs through efficient airflow and layout.

- Longer equipment life and reduced maintenance.

- Simplified compliance documentation and reporting.

- Peace of mind knowing your system was built by experienced professionals who understand industrial realities.

Partner with GSM Industrial for Safe, Compliant Operations

For more than four decades, GSM Industrial has helped manufacturers across Pennsylvania, Maryland, Delaware, and New Jersey keep their operations running safely and efficiently.

Whether you need a new RTO installed, a dust collection system integrated, or a facility-wide ventilation upgrade, our team can source the right equipment and provide the fabrication, field installation, and project management expertise to make it perform flawlessly.

FAQ: Industrial Air Pollution Control Systems

What is an industrial air pollution control system?

These systems capture and remove airborne contaminants produced during industrial processes. Common components include dust collectors, oxidizers, and filtration systems.

Does GSM Industrial manufacture air pollution control equipment?

No — GSM partners with leading manufacturers to source the right system for each application, then provides the design, fabrication, and installation expertise to make it work seamlessly.

How do RTOs and dust collectors improve safety and compliance?

They reduce harmful emissions, improve air quality, and help facilities meet OSHA and EPA requirements while extending equipment life.

How does GSM ensure minimal disruption during installation?

We pre-fabricate as much as possible, plan around your production schedule, and deploy experienced field crews who understand complex industrial environments.