In fabrication design, the difference between efficiency and costly mistakes often comes down to the tools you use. Manual processes and disjointed systems leave room for errors, wasted materials, and longer lead times, all of which erode profitability. That is why many in the metal fabrication industry are turning to integrated CAD/CAM software to streamline operations, enhance accuracy, and expedite production. This guide explores not just what CAD/CAM is but how it can be applied practically to transform your workflow.

What is CAD/CAM and Why is Integration Critical?

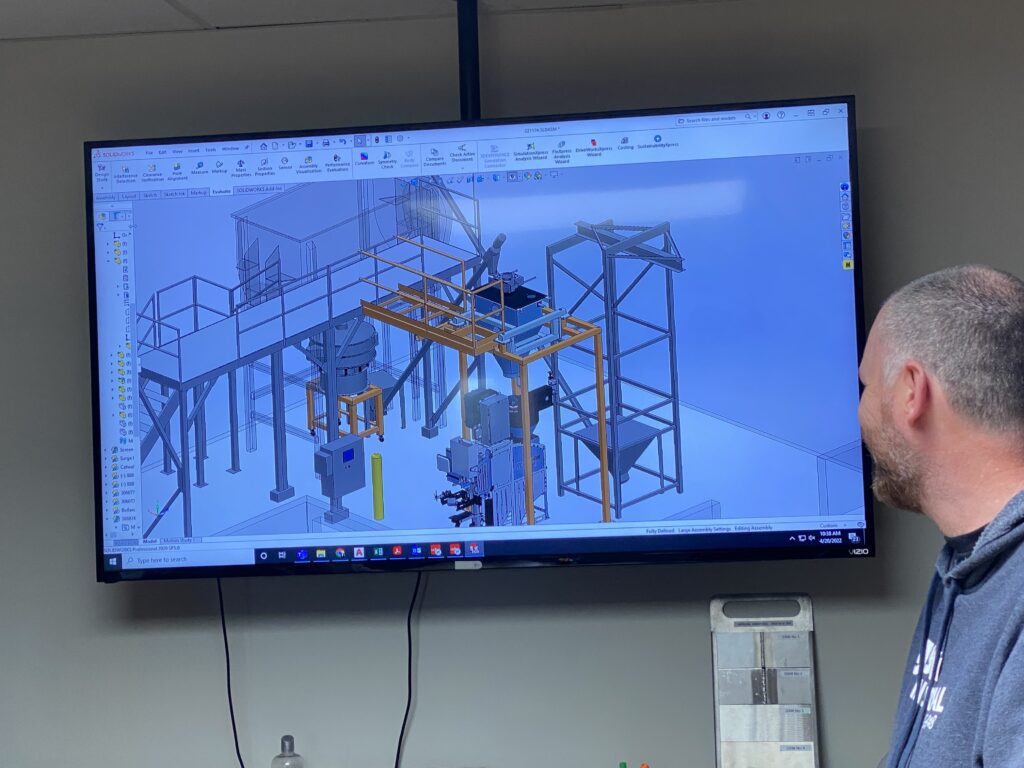

CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) are often discussed as separate tools, but their true potential is realized when they work together. CAD software allows fabricators and engineers to create precise digital models, while CAM software translates those designs into machine instructions for manufacturing.

When these platforms are siloed, information can get lost in translation. Designers may create models that require modification before being manufactured, or machinists may need to adjust files to match shop capabilities manually. Integration bridges this gap, creating a seamless pipeline from design to production. This combination eliminates unnecessary rework, reduces the risk of manual errors, and keeps projects moving forward without bottlenecks.

Benefits of a Seamless CAD/CAM Workflow

A well-integrated CAD/CAM system offers a competitive advantage. Fabricators can unlock measurable improvements across their entire operation when design and manufacturing tools work harmoniously. From reducing costly mistakes to accelerating production, the benefits of a seamless workflow touch every stage of the process.

Improved Design Accuracy and Efficiency

Fabrication design thrives on precision. With integrated CAD/CAM software, you can feel assured that every line, curve, and tolerance can be modeled digitally and carried directly into the production process. This reduces reliance on hand-drawn adjustments or verbal instructions, ensuring consistency from screen to shop floor. Efficiency improves as teams no longer waste time on redundant file transfers or corrections.

Reduced Material Waste and Production Costs

Scrapped parts and wasted materials are expensive setbacks. A unified CAD/CAM workflow allows fabricators to simulate machining paths, test designs virtually, and optimize layouts before cutting into actual materials. This proactive approach reduces the likelihood of errors, saving both raw material and labor costs.

Faster Prototyping and Time-to-Market

In today’s competitive environment, speed is just as important as accuracy. Integrated software enables rapid prototyping by streamlining the transition from design to machine-ready files. Instead of days spent reformatting and revising, prototypes can be created quickly, evaluated, and revised in hours. This means products move from concept to market faster, giving companies an edge.

Step-by-Step: Integrating CAD/CAM into Your Process

Adopting CAD/CAM integration can initially feel overwhelming, but breaking it down into manageable steps makes the transition far more approachable. By focusing on the right software, proper training, and standardized processes, fabricators can move from disconnected systems to a streamlined workflow that delivers consistent results.

Step 1: Choosing the Right Software

The foundation of any integration lies in selecting CAD and CAM platforms that complement your shop’s capabilities. Look for systems that support the types of metal fabrication you perform, whether sheet metal, structural steel, or custom components, and ensure the software is compatible with your existing machines.

Step 2: Training Your Team

Even the best software is only as effective as the people using it. Training ensures that designers, engineers, and machinists understand leveraging features and collaborating efficiently. Regular refreshers and advanced training sessions keep skills sharp as technology evolves.

Step 3: Standardizing Your File Formats

Nothing slows production like incompatible file types. Establishing file naming, formatting, and version control standards eliminates confusion and ensures smooth handoffs between design and manufacturing. This simple step avoids downtime caused by mismatched data or missing details.

Step 4: Automating Toolpath Generation

One of the greatest strengths of CAM software is its ability to automate repetitive tasks. By setting rules for toolpath generation, fabricators can drastically reduce programming time while ensuring consistent quality. Automation also reduces the risk of human error, freeing up skilled workers to focus on problem-solving and innovation.

Real-World Examples of CAD/CAM in Fabrication

Consider a fabricator producing complex metal brackets for industrial machinery. Without integration, each revision from the design team required manual programming, resulting in errors and wasted time. After adopting an integrated CAD/CAM workflow, revisions were incorporated directly into manufacturing, eliminating guesswork and significantly reducing lead times. This example demonstrates how CAD/CAM is not merely a tool, but a driver of operational excellence in metal fabrication.

Ready to Optimize Your Fabrication Process?

The challenges of manual errors, wasted materials, and long turnaround times are real, but they do not have to define your workflow. Adopting a fully integrated CAD/CAM system allows you to transform your fabrication design process into one that prioritizes accuracy, efficiency, and profitability.

At GSM Industrial, we recognize the value of integrating design and manufacturing into a single, seamless operation. Our expertise in metal fabrication, combined with advanced technology, enables clients to achieve faster production, greater precision, and lower costs. If you are ready to optimize your fabrication process and gain a competitive advantage, now is the time to act—partner with us to bring your designs to life confidently.